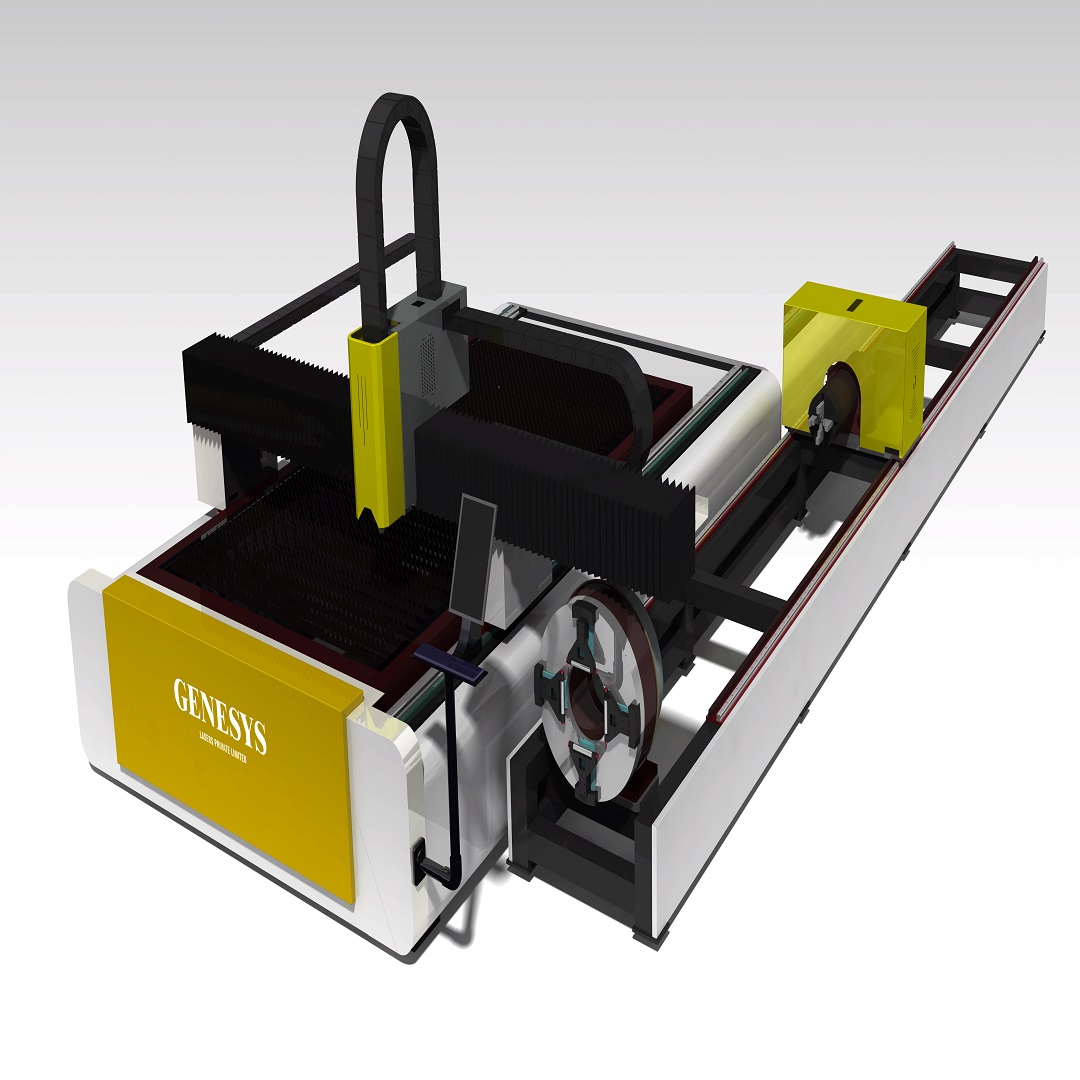

Tube Laser Cutting Machine Manufacturers in Pune

Tube Laser Cutting Machine Suppliers in Pune

As the prominent tube laser cutting machine suppliers in Pune. Reveal concealed patterns, get perfect edges, and enjoy the pick-up in your production like never before! Reveal the revolutionizing potential of tube laser cutting and increase your production capacity to unprecedented record-breaking heights.

Why Choose a Tube Laser Cutting Machine?

Gain unmatched accuracy and fine details impossible with other technologies. Replicate capacity and productivity, i.e., quicker delivery and higher output. Have flexibility to cut various material and tube sizes in one machine. Prevent material wastage, reduced secondary operations, and save production costs.

Types of Tube Laser Cutting Machine:

Being as tube laser cutting machine manufacturers in Pune, different types are there as per industrial process which are given below.

- Fiber Laser Tube Cutting Machines: Since they are able to cut more effectively, with less power, and efficiently cut metal that has reflective surfaces such as copper and aluminum. Less when it comes to operating and maintenance expenses, hence very much in need in various industrial processes.

- CO2 Laser Tube Cutting Machines: Highly sophisticated machines of limited useful application for cutting heavy material and reduced beam quality. More maintenance than fiber lasers but still a cheap way to run for specialty application.

- 3D Tube Laser Cutting Machines: With multi-axes cutting heads, they have the ability to cut complex bevel cuts, weld prep, and geometries in a single pass. Ideal for companies who need creative tube design.

- High-Speed Tube Laser Cutting Machines: These are meant for mass production and used in high-speed cutting and auto material handling systems. These are the need of high-volume output required companies.

- Compact Tube Laser Cutting Machines: With reduced space requirement and lower investment, these are suitable for small and medium companies or small-sized workshops with insufficient spaces. Even these provide wonderful benefits over traditional cutting tools.

Technical Specification of Tube Laser Cutting Machines:

We have added below a technical sheet of tube laser cutting machines in Pune that provides more technical information such as:

| Feature Category | Specification | Details/Typical Values |

| Laser Source | Type | Fiber Laser (Most common for high speed and efficiency) |

| Power Output | 2kW - 8kW (or higher, depending on material thickness and processing speed requirements) | |

| Wavelength | Typically, 1070 nm (Fiber Laser) | |

| Beam Quality (BPP) | < 2 mm*mrad (Lower values indicate a more focused and higher quality beam) | |

| Expected Lifespan | 100,000+ hours | |

| Material Handling | Chuck Type | Automatic Pneumatic or Servo-driven Chucks (Single, Double, or Multi-Chuck configurations for continuous loading and unloading) |

| Tube Diameter Range | Typically, 10 mm - 250 mm (can vary, some machines handle up to 500 mm or more) | |

| Maximum Tube Length | Standard: 6000 mm (can be extended to 9000 mm, 12000 mm, or more) | |

| Maximum Loading Capacity | Typically, up to 3000 kg or more (depending on the machine and automation system) | |

| Motion System | X, Y, Z Axis Motors | High-performance AC Servo Motors (for precise and rapid movements) |

| Maximum Positioning Speed | Typically, up to 150 m/min or higher | |

| Maximum Acceleration | Typically, up to 1.5 G or higher | |

| Positioning Accuracy | ±0.03 mm or better | |

| Repeatability | ±0.02 mm or better | |

| Cutting Head | Type | Auto-focus Cutting Head (with integrated sensors for distance control and collision avoidance) |

| Focal Length Adjustment Range | Typically, ±10 mm or more | |

| Nozzle Changing System | Automatic Nozzle Changer (reduces downtime and improves efficiency for different materials and thicknesses) | |

| Protective Window Monitoring | Integrated sensors to detect contamination or damage to the protective lens | |

| Control System | CNC Controller | Advanced industrial PC-based CNC system with user-friendly interface and advanced programming capabilities |

| Software | Dedicated CAD/CAM software for tube processing | |

| Remote Diagnostics | Capability for remote monitoring and troubleshooting by the manufacturer or service provider | |

| Dimensions & Weight | Footprint | Varies significantly based on machine configuration and automation level |

| Weight | Several tons (depending on size and features) |

Benefits of Tube Laser Cutting Machine:

Serve as tube laser cutting machine suppliers in Pune, benefits like accuracy to flexibility and many more which are given below.

- Precision and Accuracy: Cut is precise with proximity tolerance, i.e., less material loss and secondary processing. This improves the product quality and with reduced cost of production.

- Improved Cutting Rate and Productivity: Laser cutting takes three to four times less than conventional processes like sawing or punching, translating to increased quantity of production and lower lead times. These yields improved profitability.

- Material and Design Flexibility: Tube laser cutting machines cut material like steel, stainless steel, aluminum, and copper in any shape and size. Tube laser cutting machines slice complex and complex designs.

- No-Contact Cutting Process: The material is never touched by the laser beam and hence is tool-wear-free and minimizes material deformation or damage to the minimum. Cut quality is ensured and maintenance requirements are minimized.

- Low-Cost Labour and Automation: Tube laser cutting machines are made appropriate to be combined with automated loading and unloading modules in the majority of the machines in order to minimize touch and labor cost. This is applied on optimized capacity to be compatible with the product.

Applications of Tube Laser Cutting Machine:

As tube laser cutting machine manufacturers in Pune, various application for stability, ability and durability are there which are given below.

- Automotive Industry: Designing higher precision and reproducing structure pieces such as chassis, exhaust pipe, and roll cages in the automobile for higher safety and effectiveness.

- Furniture Industry: Creating complicated shapes of metal furniture support, frame, and ornament in order to get new and attractive products.

- Construction and Infrastructure: Designing construction structure steel pipes, bridges, and scaffolds in order to ensure strength, accuracy, and simplicity in the process of constructing them.

- Tube Laser Cutting for Various Applications

- Precision cutting of tough and long-lasting frames for exercise bicycles, treadmills, and other equipment for exercise with stability and long-term durability.

- HVAC (Heating, Ventilation, and Air Conditioning): Precision cutting of the tubing in the ductwork, heat exchangers, and other applications with efficiency to offer the highest efficiency to the system.

FAQs on Sheet Tube Laser Cutting Machines

A machine that can multi-task and incorporates an auxiliary flatbed laser cutter for cutting sheets and a rotary axis to cut tubes and pipe.

It is cheaper in the sense that there is one machine and not two, saves floor space, and is versatile for sheet and tube cutting companies.

Like specialty machines, they can cut steel, stainless steel, aluminum, copper, and brass, depending on the laser source and configuration of the machine.

As universal as they are, specialty machines will cut cleaner in sheets or tubes depending on model and application.