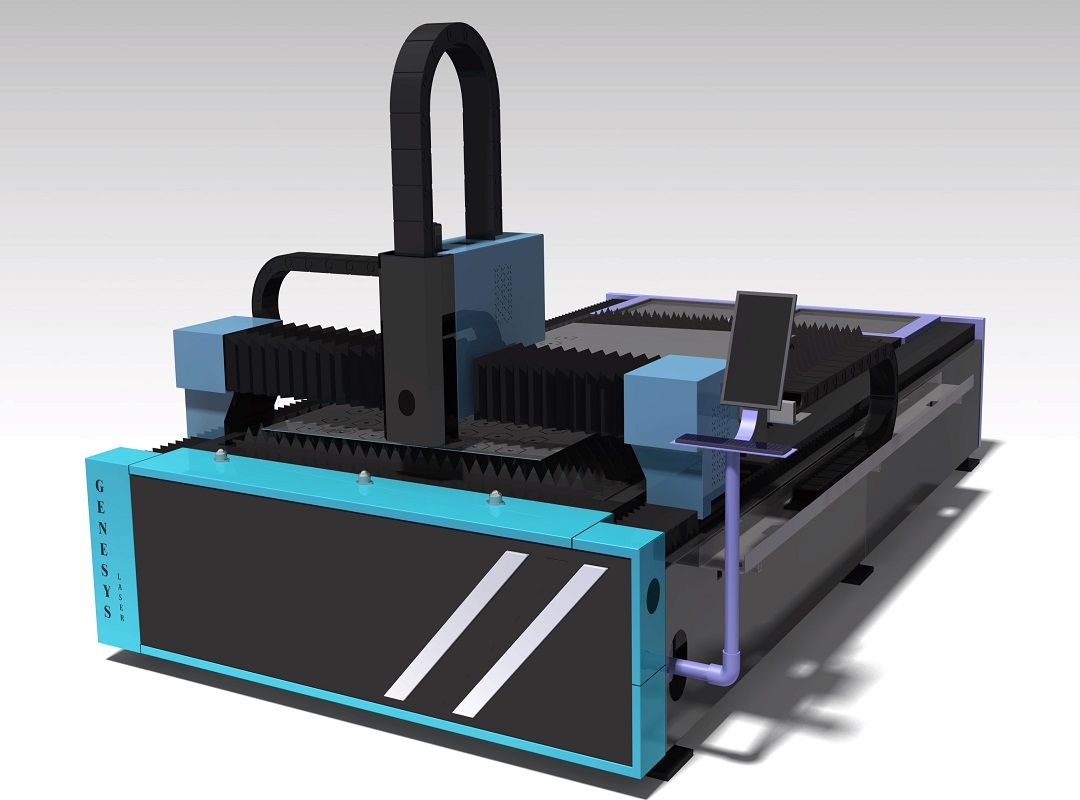

Sheet Metal Laser Cutting Machine Manufacturers in Pune

Sheet Metal Laser Cutting Machine Suppliers in Pune

As the prominent sheet metal laser cutting machine suppliers in Pune. From airplanes to automobiles, from computers to machinery, laser cutting is changing how industries cut to the world itself. Discover the wide variety of types, persuasive advantages, frequent applications, and why it's the best option to purchase a laser cutter for your metalworking requirements.

Why Use a Sheet Metal Laser Cutting Machine?

Purchase a laser cutting machine for sheet metal to advance your trade process to newer levels with unrivaled precision and speed. Minimize material wastage by a significant extent and attain complex designs, unimaginable by the traditional method. Boost your productivity level and lead the curve in today's technological competitive world. Acquire the future technology in metal manufacturing at reasonable rates with greater flexibility.

Types of Sheet Metal Laser Cutting Machine

Being as sheet metal laser cutting machine manufacturers in Pune, as per material and reflectivity types are there which are given below.

- CO2 Laser Cutters: These use carbon dioxide as the power source and are very powerful with good cut quality on thick material. CO2 lasers cut most of the time on most projects and are a fair compromise between price and performance.

- Fiber Laser Cutters: With the solid-state laser source integrated into fiber optics, fiber laser cutters provide improved cutting speed, low maintenance, and increased energy efficiency over CO2 lasers, especially for thin material and metal reflectivity.

- Nd:YAG/Nd:YVO4 Laser Cutters: Beam high laser cutters with solid state are ideally suited for deep engraving and cutting all metals. Extremely powerful but unlike fiber lasers energy efficient and maintenance-free.

- Hybrid Laser Cutters: Since there are a number of sources for the laser, i.e., use of CO2 on heavier and fiber on lighter workpieces, these cutters are on a more one-to-one basis of application selecting.

- Water-Assisted Laser Cutters: Cooling of material by water during cutting lowers heat-affected zones and inhibits thermal distortion as well as provides improved cut quality, especially in heavy material.

Technical Specification of Sheet Metal Laser Cutting Machines:

We have added below a technical sheet of tube laser cutting machines in Pune that provides more technical information such as:

| Feature Category | Specification | Typical Values/Ranges | Notes |

| Laser Source | Type | Fiber Laser (IPG, Raycus, nLIGHT, MAX Photonics) | Predominantly fiber lasers due to efficiency, beam quality, and low maintenance. |

| Wavelength | ~1070 nm | Optimal for metal cutting. | |

| Power Output | 1 kW - 30+ kW | Higher power enables thicker material cutting and faster speeds. often range from 3kW to 12kW and beyond. | |

| Beam Quality (BPP) | < 2 mm·mrad (Single-mode), < 10 mm·mrad (Multi-mode) | Lower BPP indicates a more focused beam, leading to cleaner cuts and higher precision. | |

| Motion System | Axis Configuration | 3-Axis (X, Y, Z) standard, 5-Axis optional | 5-Axis systems allow for bevel cutting and complex geometries. |

| Maximum Positioning Speed | 100 - 200+ m/min | Influences processing time, especially for intricate cuts. | |

| Maximum Acceleration | 1.5 - 3.0+ G | Affects the machine's ability to quickly change direction and cut complex shapes efficiently. | |

| Positioning Accuracy | ±0.03 - ±0.05 mm | Crucial for part precision and repeatability. | |

| Repositioning Accuracy | ±0.02 - ±0.03 mm | Indicates the machine's ability to return to a previously defined point accurately. | |

| Cutting Head | Type | Auto-Focus, Fixed Focus | Auto-focus heads automatically adjust the focal point for different materials and thicknesses. |

| Nozzle Diameter | 0.8 - 3.0+ mm (various sizes) | Selected based on material type, thickness, and assist gas. | |

| Collision Protection | Integrated sensors to prevent head damage | Important for high-speed operation and preventing costly repairs. | |

| Material Handling | Working Area (Cutting Table Size) | 1500x3000 mm, 2000x4000 mm, 2500x6000 mm (and larger) | Standard sizes vary, with larger tables accommodating larger sheets and potentially higher throughput. |

| Material Clamping | Pneumatic Clamps, Vacuum Systems | Ensures the sheet remains stable during the cutting process. | |

| Automatic Sheet Loading/Unloading Systems | Optional, various designs available | Increases automation and reduces cycle times for high-volume production. | |

| Pallet Changer (Shuttle Table) | Optional, single or dual pallet systems | Allows for loading/unloading of material while the machine is cutting, maximizing uptime. | |

| Control System | CNC Controller | Beckhoff, Siemens, Fanuc, CypCut, others | Provides the interface for programming, monitoring, and controlling the laser cutting process. |

| Software Features | Nesting, CAD/CAM integration, process parameter libraries | Optimizes material usage, simplifies programming, and provides pre-set cutting parameters for various materials and thicknesses. | |

| Remote Diagnostics and Monitoring | Increasingly common feature | Allows manufacturers or service providers to remotely access and diagnose machine issues, reducing downtime. | |

| Cooling System | Type | Industrial Water Chiller (Closed-loop) | Essential for maintaining the laser source and cutting head at optimal operating temperatures. |

| Power Requirements | Voltage/Phase | Typically, 380-480 V, 3-Phase | Varies depending on the machine power. |

| Power Consumption | 10 - 50+ kW (depending on laser power and auxiliaries) | Impacts operating costs. |

Benefits of Sheet Metal Laser Cutting Machine

Serve as sheet metal laser cutting machine suppliers in Pune, for low cost more effectiveness serves and more benefits which are given below.

- High Accuracy and Precision: Laser cutting has the very high bounds of accuracy and tolerance to nearly zero material wastage. It is very vital when very high specified accuracy level is required in an application.

- Smooth Cutting with Very High Throughput: Tools used to cut a laser are much faster compared to the conventional technologies, i.e., lower production and lead time. Higher overall profitability and efficiency.

- Material Flexibility: It has the ability to cut various metals like steel, stainless steel, aluminum, copper, and brass of varying thickness, i.e., flexible to various manufacturing processes.

- Low Distortion: Non-Contact Cutting: Laser beam never actually comes in contact with the workpiece except material deformation and stress, hence leading to less post-processing effort with clean cut.

- Cost-Effectiveness and Minimum Waste: Notwithstanding its seemingly very high front-end cost price, accuracy, high speed, and low level of loss in material of laser cutting to gain more long-term overall profitability per-part.

Applications of Sheet Metal Laser Cutting Machine

As sheet metal laser cutting machine manufacturers in Pune, in different industries as per operations applications are there which are given below.

- Automotive Industry: Machining intricate body car panel, chassis component, exhaust component, and interior component to high accuracy and reproducibility for improved motor car safety and performance.

- Aerospace Industry: Machining challenging aircraft part geometries, engine part geometries, and interior part geometries from heavy weight alloys to industry proximity.

- Electronics Industry: Accurate machining of high-precision enclosures, heat sinks, connectors, and very small stencils on PCBs where specifications are very tight for miniaturization accuracy and electronic gear operation.

- Medical Device Manufacturing: Production of surgical equipment, implants, and diagnostic devices with very high cleanliness and dimensional precision requirements, whose product directly influences the health and well-being of the patient.

- Sign and Metal Fabrication: Production of custom signs, architectural details, metal furniture, and embellishments with ornate designs and finished surfaces, as per various aesthetic and functional requirements.

FAQs on Sheet Tube Laser Cutting Machines

Any metal such as steel, stainless steel, aluminum, copper, brass, and titanium are cut by laser cutters depending on available power lasers.

Cut thickness depends on laser power and material from very thin foils to a few inches in some materials.

Even though initial usage is expensive, laser cutting is inexpensive in the long run since it has higher speed, precision, and lower wastage of material.