Pipe Laser Cutting Machine Manufacturers in Pune

Pipe Laser Cutting Machine Suppliers in Pune

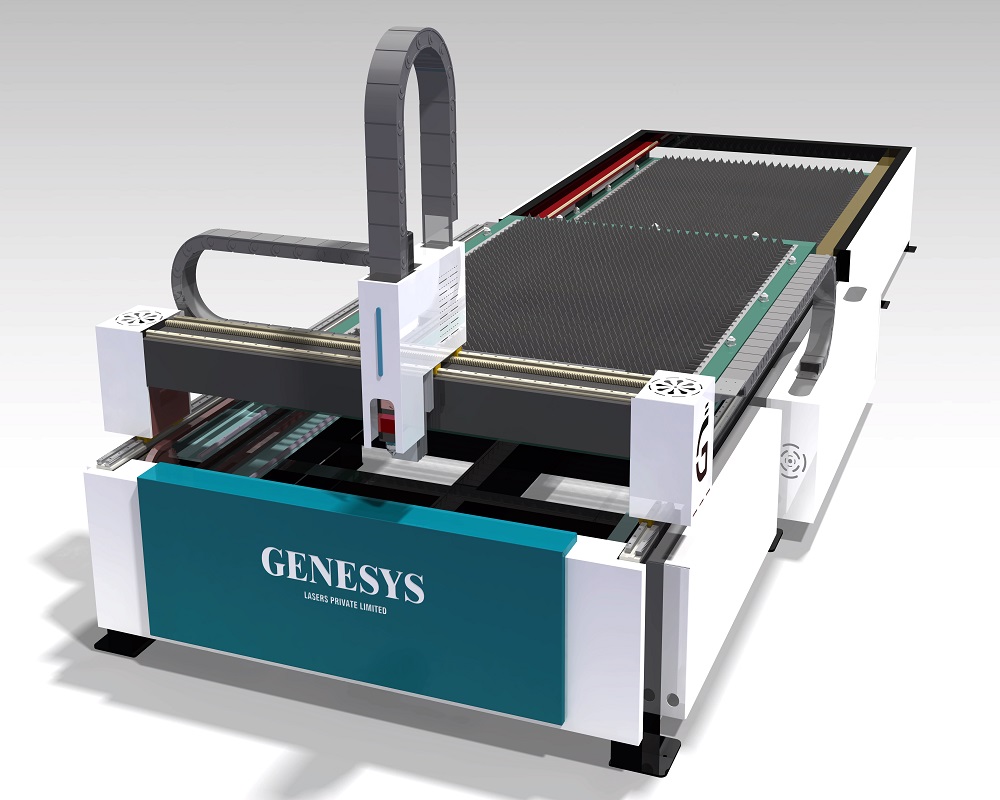

As the prominent pipe laser cutting machine suppliers in Pune. Whether you work in the automobile, construction, or aircraft industry, pipe laser cutting technology is transforming the manufacturing process to be more efficient, save on wastage, and deliver higher quality. See the strength and versatility that will propel your manufacturing to record-breaking levels.

Why to Choose Pipe Laser Cutting Machines?

Utilize Pipe Laser Cutting Machines for unrivalled precision and accurate cuts, increase your productivity and efficiency by a substantial amount, simply cut different materials and intricate designs, and minimize wastage of materials for financial savings and ecological safety.

Types of Pipe Laser Cutting Machine:

Being as pipe laser cutting machine manufacturers in Pune, as per different need of industries machines types are modified and provided which are given below.

- Fiber Laser Cutting Machines: These types of machines feature with an incorporated fiber laser source and provide great accuracy and velocity cutting of medium to thin medium-thick metal pipes with very low power consumption levels and with zero maintenance.

- CO2 Laser Cutting Machines: These can, by fitting a carbon dioxide laser on them, cut thick metal pipes and even cut through certain non-metallic substances with high-grade beams with the potential of cutting reflective material if the equipment is optimized.

- Automatic Feed Tube Laser Cutting Machines: As a result of the characteristic of possessing automatic feed mechanisms, these machines enhance the level of productivity much higher by continuously cutting the pipes at the same rate and feeding them into the machine.

- 5-Axle Tube Laser Cutting Machines: Providing industry-leading cutting technology, the machines are capable of making precise 3D cuts, bevels, and weld preparations in a single set-up, needed in close applications and intricate shapes.

- Small Diameter Tube Laser Cutting Machines: In laser cutting long and small tubes, level of precision and control needed in the applications like medical devices and electronics, the machines provide.

Technical Specification of Pipe Laser Cutting Machines:

We have added below a technical sheet of pipe laser cutting machines in Pune that provides more technical information such as:

| Parameter | Specification |

| Laser Source | Fiber Laser (IPG, Raycus, MaxPhotonics) |

| Laser Power | 1 kW – 6 kW (some models up to 12 kW for heavy pipes) |

| Pipe Diameter Range | 10 mm – 350 mm (large machines up to 610 mm) |

| Pipe Length | Standard 6 m, Optional 9 m or 12 m |

| Pipe Types | Round, Square, Rectangle, Oval, L-beam, C-channel, etc. |

| Cutting Thickness | Mild Steel: up to 20 mm; Stainless Steel: up to 12 mm; Aluminum: up to 10 mm |

| Positioning Accuracy | ±0.03 mm |

| Repositioning Accuracy | ±0.02 mm |

| Cutting Speed | 0–100 m/min (depends on material and thickness) |

| Chuck Type | Pneumatic/Servo Electric Automatic Chuck |

| Chuck Clamping Range | 10–350 mm (dual chucks for long pipe support) |

| Bevel Cutting | Optional (±45° adjustable cutting head) |

| Control System | CypCut, FSCUT 5000 Series, HypCut, or custom CNC systems |

| Software Functions | Nesting, Auto-focus, Real-time tracking, Anti-collision, Seam tracking |

| Cooling System | Water cooling (industrial-grade chiller) |

| Assist Gas | Oxygen, Nitrogen, Air |

| Power Supply | 380V, 50Hz/60Hz, 3 Phase |

| Machine Weight | 5–12 tons (depends on model size and capacity) |

Benefits of Pipe Laser Cutting Machine:

Serve as pipe laser cutting machine suppliers in Pune, for maintenance of cost and consistency in quality, preventing like these benefits serve which are given below.

- High Accuracy and High Precision: Fiber lasers possess very narrow beam focus and hence their kerf width is very thin and very accurate cuts. Their accuracy allows them to create finer shapes and reduce scrap material, thereby capital saved and better-quality components.

- Improved Cutting Speed: When cutting thin material, the fiber spotlights cut important faster than other cutting technology like waterjet or tube slice. bettered cutting speed means bettered rates of product and shorter lead times.

- Metal Cutting: The fiber lasers also cut metal materials of any form like steel, aluminum, stainless steel, copper, and brass, among other non-metallic materials. They can thus be employed for all uses in all sectors.

- Low Operating and Maintenance Costs: Fiber laser sources do not undergo cyclic maintenance regime in the long term and possess relatively low maintenance compared to CO2 lasers. They consume minimal power and thus are more expensive to run over electricity, and overall operation cost in the long term.

- Smooth Edges and Enhanced Cut Quality: Fiber spotlights produce smooth and clean edge cuts, barring the need for secondary finishing processes in utmost operations. This results in high- quality corridor with reducedpost-processing time and cost

Applications of Pipe Laser Cutting Machine:

As pipe laser cutting machine manufacturers in Pune, in different purposes, measurement and durability it is applied which are given below.

- Automotive Industry: Facilitates accurate cutting of hydraulic lines, chassis frame tubes, and exhaust pipe to ensure efficient automobile manufacturing.

- Construction and Infrastructure: Employed for cutting pipeline pipes, support bridges and construction frames, and ventilation purposes, ensuring correct measurement and ease of assembly.

- Furniture Making: Employed to achieve decorative design on metal frame furniture, decoration of tubes, and delicate cuts for assembly, resulting in beauty and long durability.

- Aerospace Applications: Used to fabricate thin but rigid tubular structures used in aircraft frames, hydraulic components, and exhaust pipes where there is high accuracy and quality conditions.

- Medical Device Manufacturing: Used in manufacturing of small and complex tubular components of medical devices, implants, and diagnostic instruments where high accuracy and clean cuts are needed to maintain the biocompatibility.

Genesys Laser Pvt Ltd is the well-known pipe laser cutting machine manufacturers in Pune as well as outstanding pipe laser cutting machine suppliers in Pune. Machines is a new generation of pipe production with higher accuracy, higher speed and higher flexibility. Their capability in cutting materials of different natures and the intricate design, wastage saving benefit and contactless processing offer them as a fortune sought by industries. Time going by and technology changing, these machines will be adding to the processes of productivity for best quality of products increasingly. Get in touch with us today!

FAQs

They can cut oval, round, rectangular, square, and special pipe and tube profiles. Machine design and chucking system would be the limiting factor.

The most often used materials are stainless steel, carbon steel, aluminium, brass, copper, and some alloys. Power supply and machine casing for lasers are problems based on various materials and thicknesses.

The most common use is with the fiber lasers since they are of low cost, possess good beam quality, and are of low maintenance. The CO2 lasers are also utilized, especially with thicker material.