Metal Cutting Machine Services in Pune

Metal Cutting Machine Services Providers in Pune

Regardless of whether you require laser's precision perfection, milling's aggressive material removal, or fabrication's neat shearing, you're in the right hands with experienced experts delivering quality perfection, lead-time reduction, and cost savings. Leap into it and experience the widespread varieties, persuading benefits, and diversified applications that make metal cutting machine services an essential supplement to your company.

Why Metal Cutting Machine Services?

By using professional metal cutting machine service, you can enjoy utilizing high technology and expertise without necessarily having to invest huge initial capital. You have the chance to work on different kinds of projects with some degree of precision and quality, ultimately impacting your manufacturing processes and cost-effectiveness as a whole. Through the use of qualified professionals, you can focus on your area of business and appreciate the use of precision metal parts tailored for your specific application.

Types of Metal Cutting Machine Services

Being as metal cutting machine service providers in Pune, for different shape and cutting approach types are modified which are given below.

- CNC Milling: With computer numerical control (CNC) and rotary cutters, milling is suitable for producing complex 3D shapes, shallow pockets, and surface finishes. Milling is a precise, repeat operation well suited to prototypes and production volumes with tight tolerances.

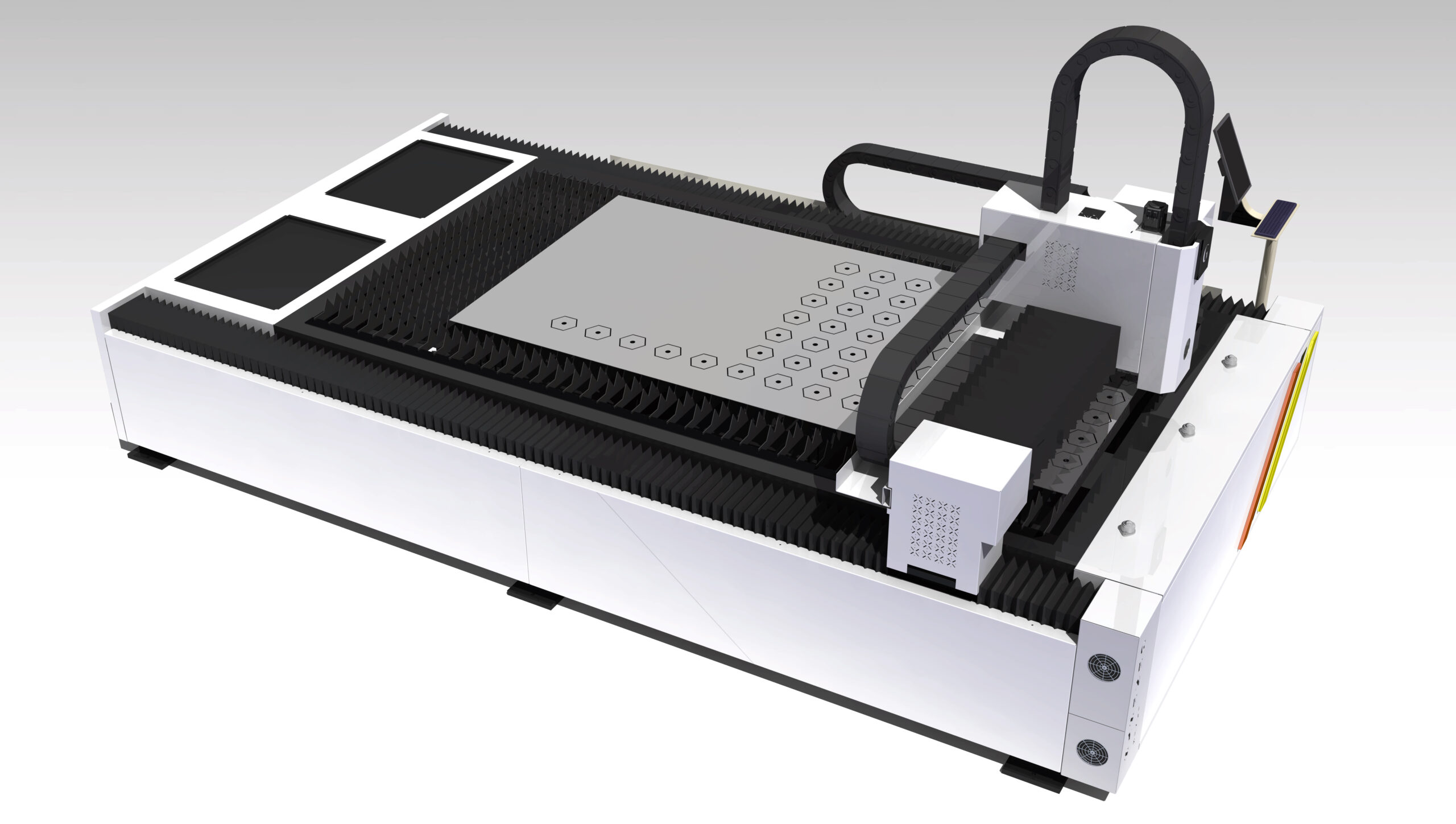

- Laser Cutting: It employs a tightly focused laser beam to make precise and clean cuts in metal thicknesses of any amount. It is also quick, can cut intricate designs, and with hardly any material loss. It is used mainly in obtaining precise profiles, cutting sheet metal, and engraving.

- Waterjet Cutting: It employs a high-speed water jet, which may be mixed with abrasive particles, to cut any metal without heating. Waterjet cutting is appropriate for heat-sensitive parts and can cut heavy pieces. It leaves smooth edges and does not generate heat-affected zones.

- Plasma Cutting: Ionized gas (plasma) is used to efficiently cut electrically conductive metals using a high-speed beam. Plasma cutting will cut more in less time, but less accurately, than laser cutting. It is a cheap method for most industrial cutting.

- Shearing: It is a mechanical process based on the application of sharp strong blades to shear straight lines on metal sheet. Shearing is a quick and efficient method for mass blank and simple shape production. Shearing is widely applied on preform metal sheets for further processing.

Benefits of Metal Cutting Machine Solution Providers in Pune:

Serve as metal cutting machine services in Pune, for improvement, time saving, capability and less waste like these benefits are given which as follow.

- Improved Accuracy and Precision: Highly sophisticated equipment and expert staff cut metal parts to precise dimensions, quality and with minimal error. Precision is particularly crucial in assemblies and applications where close tolerances are demanded.

- Cost and Time Savings: Outsourcing metal cutting saves capital investment in costly machinery, maintenance, and hiring specialist staff internally. Professional services are faster as they are expert and have optimized workflow systems.

- Access to Set of Capabilities: Metal cutting service providers provide access to set of capability of cutting and material expertise such that organizations can avail capability where they do not have in-house capability. The set allows simple production of set of complex parts.

- Less Material Waste: Precise cutting processes like laser and waterjet utilize the material optimally, reducing wastage and production cost, hence being environment-friendly too.

- Technical Competence and Quality Assurance: Professional technologists possess training and experience to work with a variety of metals and cutting processes at their optimal, and quality levels are kept high and in line with industry standards. This ability minimizes defects and rework.

Applications of Metal Cutting Machine Solution Providers in Pune:

As metal cutting machine service providers in Pune, commonly parts which are manufactured and equipment and many approaches it is applied which are given below.

- Aerospace and Automotive: High-accuracy metal parts are required in the structure of an aircraft, engine components, and a car body when high accuracy and material quality are required to achieve performance and safety.

- Construction and Infrastructure: Metal cutting services cut structural elements, frames, and other specialized metal structural components for the construction of, bridges, and other structures in infrastructural use.

- Semiconductor and Electronics: Metal parts with high tolerance which possess accurate tolerance are needed in semiconductor-processing equipment and electronic equipment as well as heat sinks. Precision-milled enclosures and laser-cut stencils are common uses.

- Medical Equipment and Devices: Medical devices, implants, and medical diagnostic equipment used in specialties such as orthopedics or oral surgery require precise metal parts that are commonly specialty parts manufactured in manufacturing.

- Metal Cutting Services: Metal cutting services make up the backbone of production components of many industrial equipment, equipment, and instruments of functional as well as robust nature.

FAQs on Sheet Tube Laser Cutting Machines

Metal cutting plants can cut a very wide variety of metals such as steel (carbon, stainless, alloy), aluminum, brass, copper, titanium, and specialty alloys. Which specific metal would be being cut on a day-to-day basis will depend upon the specific cutting process and plant capability.

The majority of advanced CNC-machines employed in metal cutting possess extremely high accuracy, typically multiples of three times thirds of a millimeter tolerance. The degree by which attainable precision will vary based on the type of machine, material, and expertise.

You will probably be requested to give a correct sketch or CAD drawing of the parts, material thickness and type you need, quantity needed, if there are tolerances or surface finishes that must be attained and when it should be produced.