Laser Marking

What is Laser Marking?

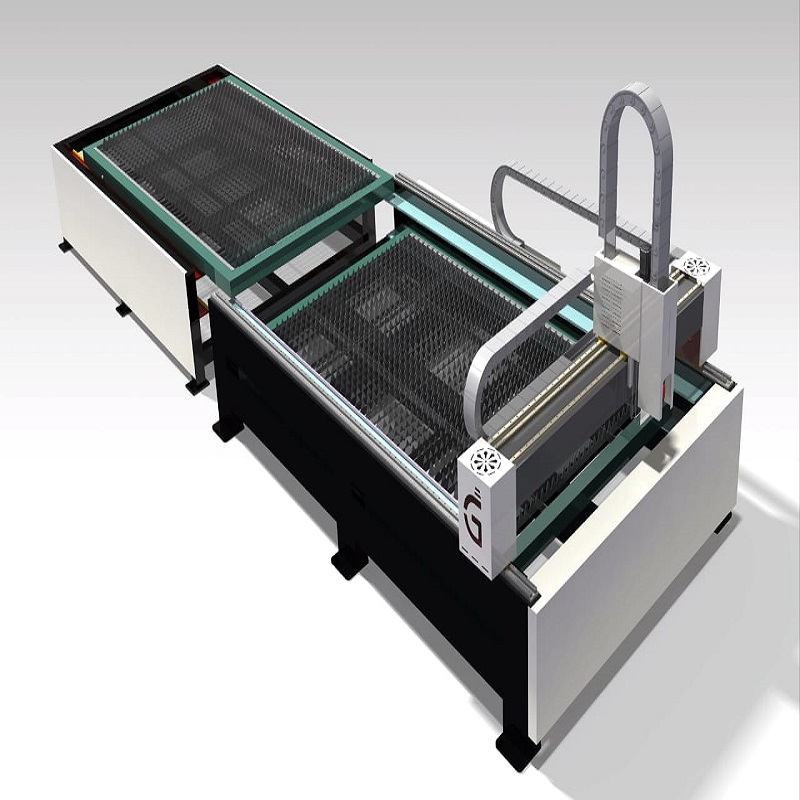

Laser Marking is for marking or labelling of work pieces and equipment with a laser beam. In this regard, different processes are distinguished, such as engraving, removing, staining, annealing and foaming. It is perfect to create an indelible mark on items and tools. Genesys LASER use a high power laser beam to cut or “draw” figures, shapes, text, or pictures into or onto objects. Traditionally, the laser is a CO2-style tube of high-power equipment, but some modern lasers can be diode-based, which is similar to a CD/DVD disc burning drive. Typical lasers are controlled via mirrors, varying magnetic fields, or other mechanical means. Already you can see that there are many variables to how laser marking or cutting will look and feel. The lowest power technique, laser marking, simply discolours the surface of an object. When the beam is intense enough to “slice” into the material, the technique is called laser engraving – for reliefs – or laser cutting – for complete penetration. Unity Marketer is a best renowned manufacturer of Industrial laser printers and laser marking machines which are used majorly for a detailed, sharper and permanent marking on the products. Such marking enables the customers to not only deal with counterfeits but also apply traceability for regulatory/supply chain track purpose.

Industrial laser printing can be done on a multiplicity of products/substrates ranging from paper and plastic products to metallic part.

Advantages:

- Permanent Marking

- Highest marking speed in the industry: can be >2000 characters/sec*

- Minimal Variable cost as no fluids/consumables required to run the machine

- Crisp & consistent marking quality with the highest resolution

- No restriction or no. of lines/font- can print anywhere within the marking window

- High uptime, less downtime due to maintenance

- Multiple lens combination with different laser technologies can be used to mark on a wide range of materials

- Ability to print 100% scannable barcode/QR code on substrates

- No wear/tear- contactless marking technology

- BTU supports complex installations