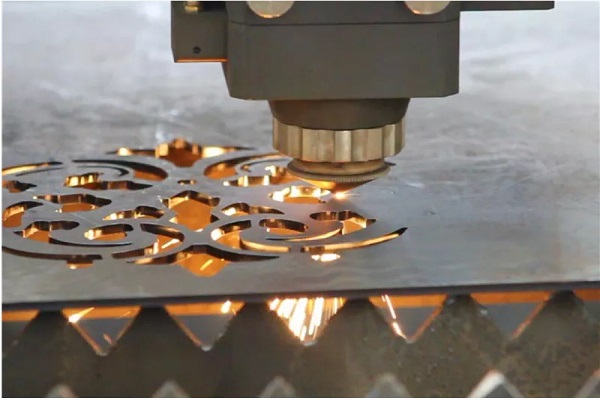

Fiber Laser Cutting Machine Services in Pune

Types of Fiber Laser Cutting Machine Service:

Being as fiber laser cutting machine service providers in Pune, different cutting purposes types modified after industry analysis which are given below

- Open-Bed Fiber Laser: Offers convenient unloading and loading of material and is suitable for overweight, out-of-square-sized parts and job shops with high number of operations.

- Pallet Changer Fiber Laser: Offers double pallets with double-side cutting on one side and loading/unloading on the other side and offers maximum uptime and throughputs for repetitive manufacturing.

- Fiber Laser Enclosed and Automation: Offers greater safety, fume extraction, and packaged robot packages in general for precise cutting of planned material, best suited for large-scale repeated cutting.

- Fiber Pipe and Tube Laser: Typically used to precision cut round and профильные (profiled) material precisely and economically, extensively used in the manufacturing industry like building and automobile.

- 3D Fiber Laser Cutting Machine: Multi-axis cutting to obtain complex geometry and curved shape, highest detail and minimum secondary operations.

Benefits of Fiber Laser Cutting Machine Solution Providers in Pune:

Serve as laser cutting machine services in Pune, gives different types of benefits which have different uniqueness and creative design which are given below.

- Enhanced Quality and Accuracy: Higher focus ability of fiber laser to obtain smooth cut with close tolerance and minimum heat-affected zone, minimum post-processing and maximum quality of the part.

- Unmatched Speed and Productivity: Fiber laser cutting is quicker than the remainder of the waterjet or plasma cutting processes with quick lead time, quick turnaround, and lower per part.

- Material Process ability Flexibility: Fiber lasers provide material process ability for stainless steel cutting, steel cutting, aluminum cutting, copper cutting, and brass cutting irrespective of material thickness, thereby flexibility to wide categories of applications.

- Low Operating and Maintenance Cost: Fiber laser is power-efficient and less maintenance than CO2 laser, and therefore there is huge saving in downtime cost, electricity, and consumable.

- Improved Design Capability: High precision and capability of fiber laser offer precise detailed cutting, delicate patterns, and complex shapes to cut, and therefore this gives new and creative design methods and product uniqueness.

Applications of Fiber Laser Cutting Machine Solution Providers:

As fiber laser cutting machine service providers in Pune, to design different parts in industries and manufacturing purposes it applied which are given below.

- Automotive Industry: Used in shearing of body panel, interior, exhaust, and chassis components for weight reduction and cost savings.

- Aeronautical Industry: Used in shearing of structural aircraft components, engine components, and interior components from high-specification aluminum and titanium alloys.

- Semiconductor and Electronics Industry: Used in shearing thin stencils, board layout, and little components from thin material with extreme precision and minimum wastage metal foil.

- Medical Device Manufacturing: Applied in the production of surgical devices, implants, and medical devices from high tolerance and biocompatible material for safeguarding the patient and auto-mating the device self.

- Sheet Metal Forming: Applied daily for cutting large amounts of metal sheets to a specific shape to build enclosures, brackets, panels, and other structural or design parts in industries.

FAQs on Sheet Tube Laser Cutting Machines

Cutting through metals such as carbon steel, stainless steel, aluminum, copper, brass, titanium, and special alloys will be best delivered by the services of fiber laser cutting. Work thickness capability will be determined by the power of the laser machine.

Cutting is extremely accurate, and normal use tolerance is ±0.1 mm (0.004 inches) or better depending on application. That is to the degree of accuracy that enables cutting to specification and eliminates second-stage finishing requirements.

You would typically be asked to supply CAD drawings in DWG or DXF file format, material thickness and type, quantity, and special finish or due date.