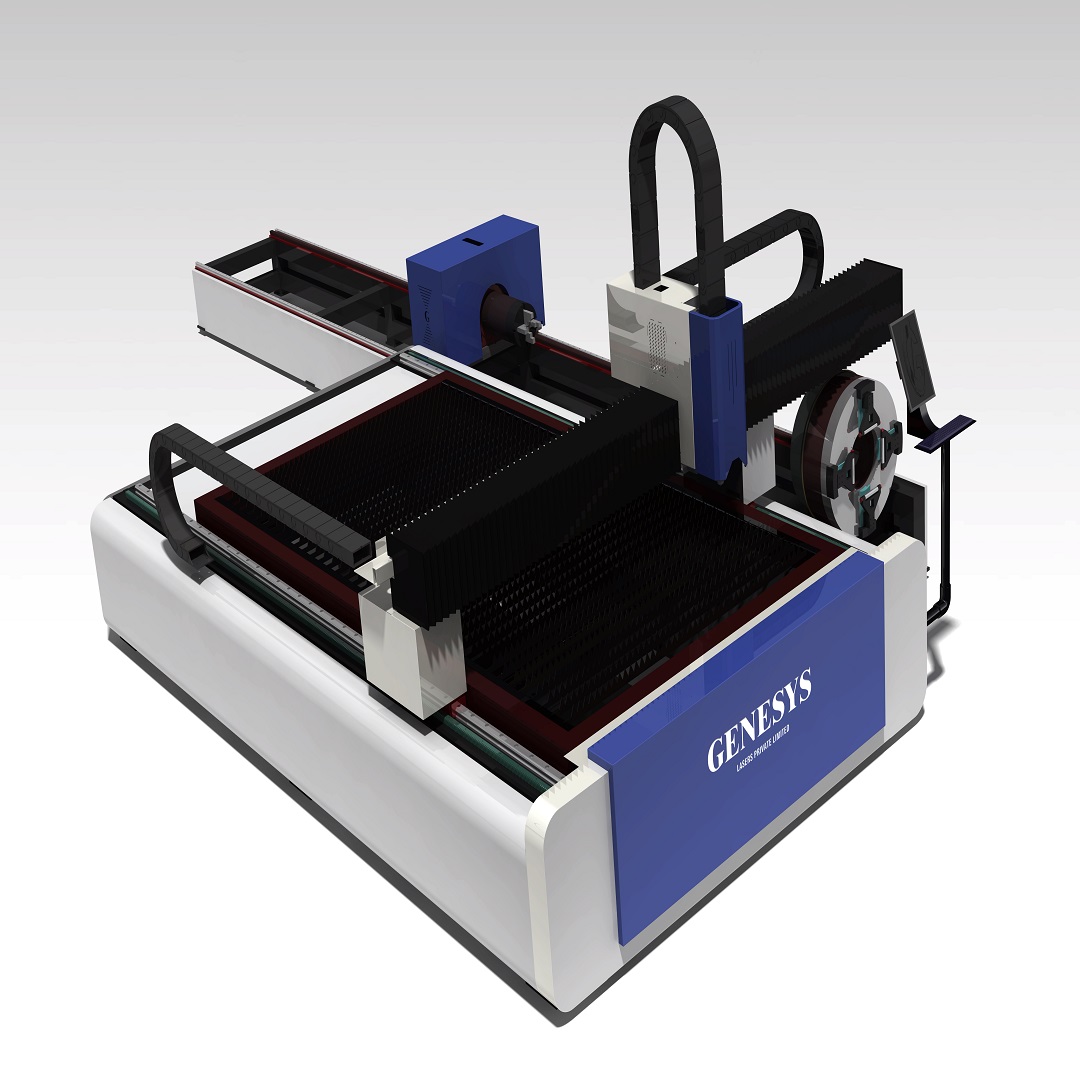

Fiber Laser Cutting Machine Manufacturers in Pune

Genesys Laser Pvt Ltd is the leading fiber laser cutting machine manufacturers in Pune and suppliers in Pune, prepare to be amazed by the Fiber Laser machine. As the speed of the coming artificial age is going overdrive, perfection, haste, and versatility are the unquestioned rulers. These machines leverage the goliath strength of powerful laser beams enabled by fiber optic to cut raw material into accurate shapes with unparalleled precision.

Leading Fiber Laser Cutting Machine Suppliers in Pune

We are one of the trusted fiber laser cutting machine suppliers in Pune. Think of a machine so smoothly capable of cutting through metal and non-metals with such delicacy and ease that traditional means can only hope for.

Why to Choose Fiber Laser Cutting Machine?

Fiber laser cutting machine has some better reasons why companies can be improved by increasing their production capacity:

Fiber lasers emit ultra-concentrated and ultra-narrow laser beam, which offers ultra-accurate cuts with ultra-thin kerf (shaves). Fiber lasers cut very rapidly compared to other cutting machines like CO2 lasers, plasma, or waterjet. These have one fiber laser that is applied to cut various unrelated materials. That is their goal which will cost them in most manufacturing uses.

Types of Fiber Laser Cutting Machine:

Being as fiber laser cutting machine manufacturers in Pune, as per different need, treatment and industries need types are there which are given below.

- Low-Power Fiber Lasers: Used for cutting thin plastic, sheet metal, and electronics separately.

- Medium-Power Fiber Lasers: Cutting fast with good thickness and material such as metals and alloys are auto and aerospace industries.

- High-Power Fiber Lasers: Cutting large amounts on hard material and used in shipyard, construction, and heavy machines separately.

- Pulsed Fiber Lasers: These emit pulsed laser light and used in laser marking, material treatment, and micro-machining.

- Continuous Wave (CW) Fiber Lasers: Continuous constant emission laser light lasers and industrially employed for process applications such as welding, cutting, engraving, and marking.

- Single Table Fiber Laser Cutting Machine: Single-table cutting machine and employed for small work and general cutting.

- Double Table Fiber Laser Cutting Machine: As double-table cutting, there is automatic cutting and greater productivity.

Technical Specification of Fiber Laser Cutting Machine:

We've added below a specialized distance of fiber laser cutting machine in Pune that provides further specialized information

| Specification | Details |

| Standard Working size | 1200*1200, 2500*1300, 3000*1500, 4000*2000 (mm) |

| Laser Power | 300W, 500W, 750W, 1000W, 1200W, 2000W, 3000W, 5000W |

| Cost Range | $20000.00 – $30000.00 |

| Positioning Accuracy | ±0.02 mm |

| Repositioning Accuracy | ±0.01 mm |

| Maximum Cutting Speed | 140 m/min (depends on material and thickness) |

| Cooling System | Water-cooled chiller |

| Power Supply Requirements | 380V ±10%, 50/60Hz, 3-phase |

Benefits of Fiber Laser Cutting Machine:

Serve as fiber laser cutting machine suppliers in Pune, different benefits and as per quality given which are given below.

- High Accuracy and High Precision: Fiber lasers possess very narrow beam focus and hence their kerf width is very thin and very accurate cuts. Their accuracy allows them to create finer shapes and reduce scrap material, thereby capital saved and better-quality components.

- Improved Cutting Speed: When cutting thin material, the fiber spotlights cut important faster than other cutting technology like waterjet or tube slice. bettered cutting speed means bettered rates of product and shorter lead times.

- Metal Cutting: The fiber lasers also cut metal materials of any form like steel, aluminum, stainless steel, copper, and brass, among other non-metallic materials. They can thus be employed for all uses in all sectors.

- Low Operating and Maintenance Costs: Fiber laser sources do not undergo cyclic maintenance regime in the long term and possess relatively low maintenance compared to CO2 lasers. They consume minimal power and thus are more expensive to run over electricity, and overall operation cost in the long term.

- Smooth Edges and Enhanced Cut Quality: Fiber spotlights produce smooth and clean edge cuts, barring the need for secondary finishing processes in utmost operations. This results in high- quality corridor with reducedpost-processing time and cost

Applications of Fiber Laser Cutting Machine:

As fiber laser cutting machine manufacturers in Pune, different applications for accuracy and quality need which is given below.

- Automotive Industry: Used in accurate cutting of different metallic motor vehicle body components, chassis, and interior trim with ease and accuracy for effective production and light weight.

- Aerospace Industry: Used to cut state-of-the-art components of chosen alloys like aluminium and titanium for aircraft structure and engine components where accuracy and hardness are required.

- Sheet Metal Fabrication: Mainly applied to cut sheet metal into intricate sizes and shapes for enclosures, panels, brackets, and other parts for industries to provide flexibility and quick prototyping.

- Electronics Industry: Applied to cut thin metal sheet and utilized to create accurate stencils and masks for electronic components and printed circuit boards with accurate precision and heat-free cuts.

- Medical Device Production: Used for producing thin medical devices for surgery, implants, and stainless steel and other biocompatible metal-based medical devices with precise accuracy and strict quality.

Fibre Metal Ray Cutting Machine Applicable Accoutrements- Stainless sword distance, carbon sword, amalgamation sword, silicon sword, spring sword, Aluminium, aluminium amalgamation, galvanized distance aluminium zinc plate, pickling board, tableware, gold, titanium, other essence distance, essence pipe slice.

Genesys Laser Pvt Ltd is the well-known fiber laser cutting machine manufacturers in Pune as well as fiber laser cutting machine suppliers in Pune are a materials processing breakthrough in combination. Their precision, velocity, diversity, and accessibility have made them an unstoppable support column of industrial production in the modern era. From advanced medical equipment to huge aerospace components, fiber laser cutting machines enable industries to produce at ever-increasing levels of innovation, quality, and efficiency, and drive innovation across all types of industry. As with every new development in technology, fiber laser cutting will further define the manufacturing future. Get in touch with us today!

FAQs

The fiber lasers are appropriate to shear the non-ferrous metals like stainless steel, steel, brass, copper, and aluminum. Even though the fiber lasers are applied on the metals in gigantic quantities, the fiber lasers are not generally appropriate to shear the non-metal materials.

Fiber lasers will cut more efficiently (particularly on thin metal), consume less power, be easier to maintain, and cut reflective metals more efficiently than CO2 lasers.

Fibre laser sources have extremely long working life with a typical working life of approximately 100,000 hours before even they start to fail, many times that of a CO2 laser.