Metal Laser Cutting Machine Manufacturers and Suppliers in Mumbai

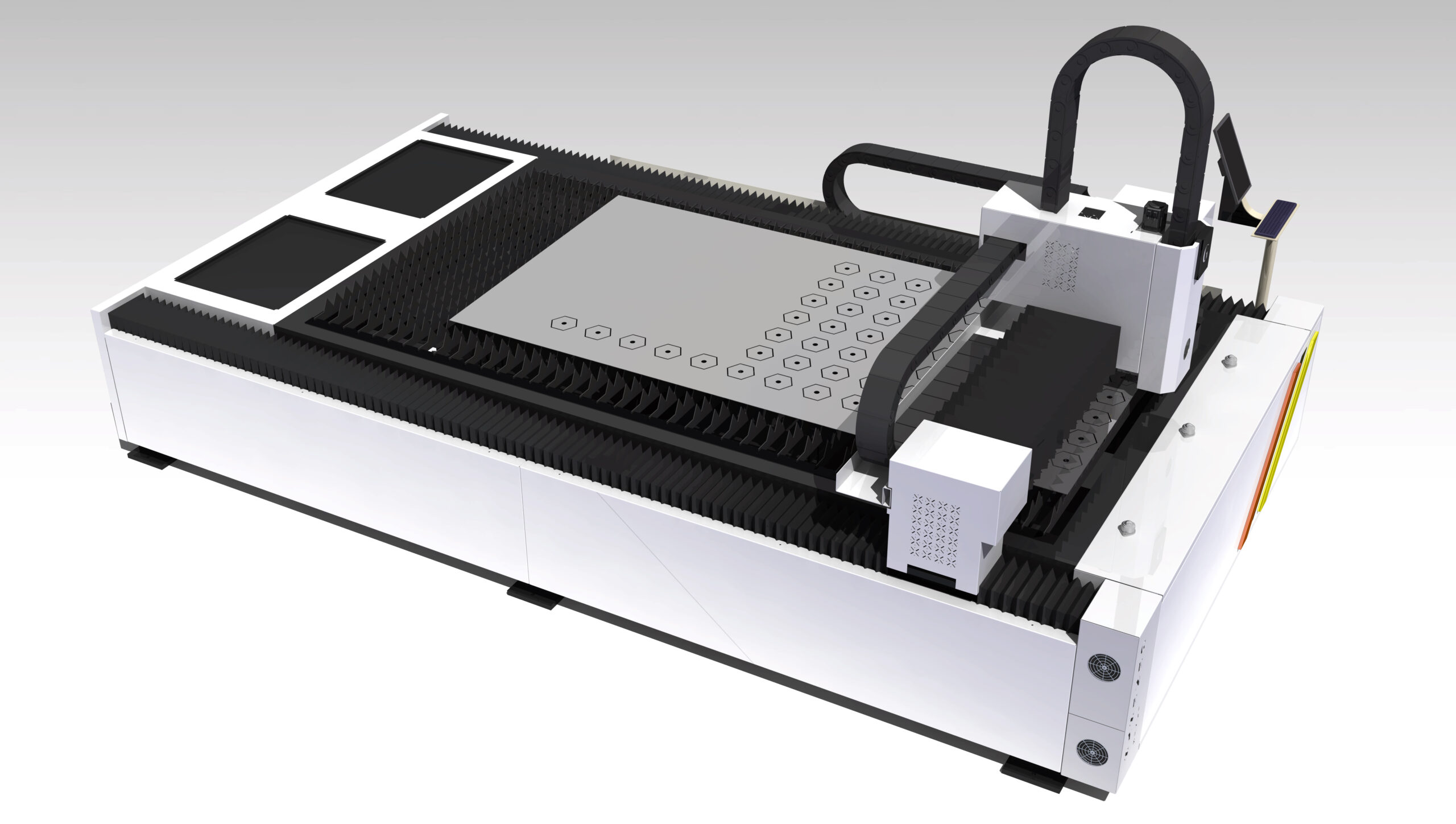

Genesys Laser Pvt Ltd is the foremost metal laser cutting machine manufacturers in Mumbai. Since industrialization is happening at breakneck speeds, it is only logical to demand innovative design, rapid prototyping, and rapid mass production at record levels of accuracy. That's where the laser cutting machine steps in – an unmatched machine that uses focused light energy to cut and shape raw material into exactly finished parts.

Genesys Laser Pvt Ltd is the foremost metal laser cutting machine manufacturers in Mumbai. Since industrialization is happening at breakneck speeds, it is only logical to demand innovative design, rapid prototyping, and rapid mass production at record levels of accuracy. That's where the laser cutting machine steps in – an unmatched machine that uses focused light energy to cut and shape raw material into exactly finished parts.

Why Use a Laser Cutting Machine for Metal

The selection of laser cutting machine is the selection of unmatched rate of production and precise process for metal. With the ability to cut through this gargantuan range of material, it has an endless number of design and application potential. And on top of all this, there is minimal wastage material and a silky-smooth finish in the case of the non-contact process. Your enterprise will be a leader in high-tech and optimal production in the business segment in manufacturing with investment in laser cutting technology.

Types of Metal Laser Cutting Machine

Being as premier metal laser cutting machine manufacturers in Mumbai, for different cutting process like metallic and nonmetallic which types modified which are given below.

- Crystal Laser Cutters (Disk Lasers): High-beam-quality, high-power solid-state lasers and high-power lasers, and were primarily applied in hard industrial cutting applications, i.e., metals.

- CO2 Laser Cutters: These will probably be the most versatile machines, employing a combination gas to generate a high-watt infrared laser beam. These are suited best for cutting and engraving very commonly non-metallic material like wood, paper, cloth, and plastic, and thin metals.

- Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) Laser Cutters: They are a solid-state laser and a tightly focused beam with high-power beam, utilized to engrave and cut metal and non-metal substrates. We are quicker but will be maintenance intensive than fiber lasers.

- Nd:YVO4 (Neodymium-doped Yttrium Orthovanadate) Laser Cutters: These are similar to Nd:YAG lasers and are top-of-the-line beam solid-state lasers. We are mainly used for precise marking and engraving.

- Fiber Laser Cutters: Fiber laser is creating extremely smart beam with solid-state technology in the form of increased focus and power concentration. They are cutting very deeply into all multi-metals such as steel, aluminum, and brass with satisfactory accuracy and speed.

Technical Specification of Laser Cutting Machine for Metal

We have added below a technical sheet of metal laser cutting machine in Mumbai that provides more technical information such as:

Parameter | Specification | Description |

Laser Source Type | Fiber Laser | Dominant technology for metal cutting due to high efficiency, excellent beam quality, and low maintenance. |

Laser Power | 1 kW to 60 kW+ | Directly impacts cutting speed and thickness capacity. Common industrial powers are 6 kW for general fabrication and 12-20 kW for high-speed, thick plate cutting. |

Work Area | 3000 x 1500 mm to 6000 x 2500 mm | Standard sizes to accommodate common metal sheet dimensions. Larger custom tables are available. Dual-platform shuttle tables are a standard feature to minimize downtime during material loading/unloading. |

Cutting Thickness | Up to 60 mm (mild steel) | Varies greatly with laser power and material. For example, a 6 kW laser can cut up to 25 mm mild steel and 12 mm stainless steel. A 30 kW laser can cut up to 50 mm mild steel. |

Positioning Accuracy | ±0.05 mm or better | The machine's precision in moving the cutting head to a specific point. Crucial for producing intricate parts and maintaining tight tolerances. |

Repeatability | ±0.03 mm | The ability of the machine to return to the same programmed position reliably. |

Max. Cutting Speed | Up to 100 m/min | Achieved on thin gauge materials (e.g., 1 mm stainless steel). The speed decreases significantly with thicker materials. |

Kerf Width | 0.1 mm to 0.4 mm | The width of the cut. A narrow kerf minimizes material waste and allows for finer detail cutting. |

Auxiliary Gases | Oxygen (O2) and Nitrogen (N2) | Used to assist the cutting process. O2 is used for mild steel to promote a faster, exothermic cut. N2 is used for stainless steel and aluminum to achieve an oxidation-free edge. |

CNC Control System | Professional Laser-specific CNC | Features include real-time power control, automatic focus adjustment, and integrated nesting software for material optimization. |

Drive System | High-precision Servo Motors and Linear Guides | Ensures rapid acceleration, deceleration, and smooth, accurate motion of the cutting head. |

Automation | Automatic focus, nozzle changing, and sheet loaders | Advanced features that reduce manual intervention and increase productivity. Fully automated systems with robotic arms for part sorting are common in high-volume production environments. |

Safety Features | Fully enclosed cutting area, safety glass, and fume extraction systems | Essential for operator safety, protecting against laser radiation and harmful fumes. |

Benefits of Metal Laser Cutting Machine

Serve as laser cutting machine for metal suppliers in Mumbai, as per process requirement precise benefits are given which are given below.

- High Precision and High Accuracy: The laser cutting machine gives high accuracy and precision to cut very slim with tolerances. Clean precise edges are being given by the convergent beam laser, therefore reducing post-process requirements.

- Material Flexibility: The majority of the laser cutting machines are capable of cutting virtually any kind of material from non-metallic materials like wood, acrylic, and cloth to metallic materials like steel and aluminum.

- Speed and Productivity: The reason for high-speed cutting being feasible through laser cutting machines on the material, i.e., processing time is significantly shorter than in conventional cutting.

- Versatility and Flexibility: Laser cutting is able to cut very complex geometry and very custom parts quickly. Redesign on the fly can be achieved with software so that on-the-fly prototyping and custom runs can be achieved without new tools.

- Non-Contact Process: Laser cutting process is a non-contact process as there is no tool contact with the material. Laser cutting machine for metal service providers in Mumbai minimizes tool wear, provides minimum scope of material damage or bending, and produces precise and fine cuts without exposing them to mechanical stress.

Applications of Laser Cutting Machine for Metal:

As laser cutting machine for metal manufacturers in Mumbai, for recompose of material applications are there which are given below.

- Aerospace Industry: Laser cutting relies on the aerospace industry in cutting precisely through delicate pieces of thin but high-strength materials like aluminum alloys and composite material. Material purity and precision are purely required and these are provided for by laser cutting by making them flawless.

- Electronics Industry: Laser cutting machine for metal service providers in Mumbai is an essential process utilized in the manufacturing of electronic components, manufacturing of circuit boards, and manufacturing of enclosures with loss-less and precise cutting of material.

- Sign and Display Industry: Laser cutting has found extensive use in the manufacture of complex signs, displays, and display billboards made of metal, wood, and acrylic. Because it can cut detailed patterns and engravings with a better finish quality.

- Automotive Sector: Laser cutting technology is widely employed in precise cutting of automotive body panels, trim parts, airbags, and gaskets. It cuts intricate shapes and materials with ease and thus is a perfect luxury of new car manufacturing practice.

- Medical Device Production: The medical sector applies laser cutting to fabricate surgical instruments, implants, and parts of medical instruments from stainless steel and polymers. Pure and precise cuts render lifesaving medical devices efficient and safe at maximum capability.

Genesys Laser Pvt Ltd is the outstanding laser cutting machine for metal manufacturers, suppliers, and service providers in Mumbai, with technology, laser cutting machines for metals are certainly propelling the automobile in the second-generation industrial manufacturing with innovation and efficiency in most industries. Our precision ability to cut out materials and provide detailed designs with high precision has transformed overall manufacturing processes. Machines are point-of-focus machines in any contemporary world manufacturing industry with an ideal combination of flexibility, precision, and speed.

FAQs on Sheet Tube Laser Cutting Machines

Laser source, motion control (motors and rails), optics (mirrors, lens), exhaust system.

Good precision, intricate shape, better surface finish, non-contact process, and versatility.

Wood, acrylic, paper, fabrics, plastics, thin metal.

Machine that emits high-energy laser onto material, burns or vaporizes it, melts it into the desired path.